What are pigments?

What are pigments?

Pigments are insoluble organic or inorganic particles added to the polymer base to give a specific color to the plastic.

-

Pigments that are organic in nature are hard to disperse and tend to form agglomerates (clumps of pigment particles). These agglomerates can cause spots and specks in the final product.

- On the other hand, inorganic pigments (like metal oxides, sulfides, and carbon blacks) get more easily dispersed in the resin. Amongst the inorganic pigments titanium dioxide is the most widely used pigment in the plastics industry.

How are pigments classified?

Pigment families are mainly categorized into:

- Organic pigments

- Inorganic Pigments

- Carbon blacks

- White pigments

- Special effect pigments

- Aluminum pigments, and

- Other pigments

Typical performance properties

-

Weatherability/Aging – Exposure to sunlight and some artificial lights can have adverse effects on the useful life of plastic products. So polymers that are frequently used outdoors need UV protection. Hence, they also require weather-resistant pigments.

To assess weathering resistance in practice, you must use outdoor exposure tests in the climatic region(s) concerned. This is not always feasible. The widely used alternative is accelerated testing: CYCLE WOM 119.

We must consider the light stabilizer system together with:

-

the pigment formulation and

- the specified fastness criteria for the final product.

- Light Fastness – It is a measure of the color fastness of light over time. This property measures the color change of plastics when used in indoor applications. Pigment selection for plastics used in indoor applications depends on:

- polymer type

- concentration of the pigment

- presence of titanium dioxide (which typically accelerates fading)

- required light fastness

- service conditions

If a pigment has good Light Fastness, it does not always mean that it has good weather-fastness.

Pigment performance can also be influenced by:

-

surface of the article

- processing heat history, and

- stabilization package

Generally, inorganic pigments exhibit superior light fastness than organic pigments.

- Warping/Nucleation – The two factors that determine the final properties of a plastic article are:

- the degree of crystallinity and

- the speed of crystallization

Organic pigments influence these parameters during the cooling phase of plastic processing. Particularly in HDPE injection molding.

This can result in:

- Reduced mechanical stability

- Impact on dimensional stability

Typical applications where this effect becomes important are containers, crates,

and caps & closures. Pigments can be divided into three groups, depending on their influence on the shrinkage

of HDPE injection molding systems. This distortion tendency is described as:

| Non-warping

|

No significant influence, either in lab tests or in practice

|

| Low-warping

|

Slight influence, as detected in lab tests, but has been successfully used in practice

|

| Warping

|

Significant influence, both in lab tests and in practice. Not recommended for

this application or only in combination with specific, warpage-reducing additives

|

-

Transparency – Usually, transparency is obtained by reducing pigment particle size as possible. This is achieved by surrounding the particles as soon as they are formed with a coating, which prevents the growth of crystals. The most common products used for this coating are rosin or rosin derivatives. This is particularly useful for printing ink pigments that have high transparency. It has the added advantage that such pigments are more easily dispersed.

Iron oxide pigments can be opaque or transparent. The transparent variety is an important group of inorganic pigments as they are widely used for metallic finishes. Their high level of transparency gives them an attractive finish. Their weatherability resistance improves the weatherability of pigments with which they can be combined. This is known as a synergistic effect. Transparent iron oxides depend on the particles being unusually small, and having a crystal shape.

-

Effect of Dispersion on Transparency - The dispersion process can influence transparency. It involves breaking up agglomerates of particles into individual primary particles. However, primary particles are not split up by the dispersion process. All one can do is to make full use of the pigments original particle size. Good dispersion will maximize the transparency of a small particle.

-

Measurement of transparency - It is assessed by applying the coating over a black and white contrast chart, and measuring the color difference. The greater the color difference, the higher the transparency.

What are the types of organic pigments suitable for plastics?

What are the types of organic pigments suitable for plastics?

Organic pigments refer to a wide range of chemical families and cover a wide spectrum of properties. They are mainly used for applications needing high tinting strength and brilliant shades while inorganic pigments are mainly useful where high opacity is needed.

We can distinguish three main categories of organic pigments:

- Polycyclic

- Azo (Mono- and Di-)

- Metal complexes

For each category, classical and high performances pigments are available. The performances of the pigment will depend on:

- Chemical structures

- Surface properties

- Crystallinity

- Particle size and size distribution

Now let's take a look at the organic components driving a specific color pigment.

Yellow Pigments Yellow Pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which Used

|

|

Anthraquinone

|

Medium to high color strength, transparency

|

- Good heat, light and migration fastness

- Good to excellent weather to fastness

|

PS, PP, LDPE, HDPE, PMMA, PC, PBT, PET

|

|

Diazo pigments

|

High color strength, wide range of shade and opacity

|

- good heat, light and migration fastness

- Medium to good weathering

|

PVC, LDPE,HDE,PP, PS, HDPE

|

|

Isoindolinone

|

Medium to high color, strength, greenish, reddish yellow, and orange

|

- Excellent heat, light and migration fastness

- Excellent weathering, particularly at low concentration and TiO2 reduction

|

PVC, PS, LDPE, HDPE, PP

|

|

Mono Azo salts

|

Medium color strength

|

- Good heat, light and migration fastness

- Low weathering

|

PVC, LDPE, HDPE, PP, PS

|

Orange Pigments Orange Pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which used

|

|

Benzimidazolone

|

High saturation and opacity

|

- Good heat, light and migration fastness

- Medium weathering

|

PVC, PS, LDPE, HDPE, PP, ABS

|

|

Diketo pyrrolo pyrrole (DPP)

|

Very pure and brilliant shade, high color strength, wide range of

shade and opacity

|

- Good to excellent heat, light and migration fastness

- Reds show good to excellent weather resistance

|

PVC, PS, LDPE, HDPE, PP

|

|

Isoindolinone

|

Medium to high color, strength, greenish, reddish yellow, and orange

|

- Excellent heat, light and migration fastness

- Excellent weathering, particularly at low concentration and TiO2 reduction

|

PVC, PS, LDPE, HDPE, PP

|

Brown Pigments Brown Pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which Used

|

|

Diazo pigments

|

High color strength, wide range of shade and opacity

|

- Good heat, light and migration fastness

- Medium to good weathering

|

PVC

|

Red pigments Red pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which Used

|

|

Anthraquinone

|

Medium to high color strength, transparency

|

- Good heat, light and migration fastness

- Good to excellent weather fastness

|

PS, PP, LDPE, HDPE

|

|

BONA Lake

|

High color strength, pure shade

|

- Low heat and light fastness

- Good migration

|

PVC, PS, LDPE, PP

|

|

Diazo pigments

|

High color strength, wide range of shade and opacity

|

- Good heat, light and migration fastness

- Medium to good weathering

|

PVC, PS, LDPE, HDPE, PP

|

|

Diketo pyrrolo pyrrole (DPP)

|

Very pure and brilliant shade, high color strength, wide range of

shade and opacity

|

- Good to excellent heat, light and migration fastness

- Reds show good to excellent weather resistance

|

PVC, LDPE, HDPE, PP, PS

|

|

Naphthol Lake

|

High color strength, pure shade

|

- Good heat and migration fastness

- Low light fastness

|

PVC, PS, LDPE

|

|

Quinacridone

|

Medium to high color, strength, bluish red and violet

|

- Good heat, light and migration fastness

- Good to excellent weathering, particularly in TiO2 reduction

|

PVC, HDPE, PP, PS, LDPE, PA

|

Blue pigments Blue pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which Used

|

|

Anthraquinone

|

Medium to high color strength, transparency

|

- Good heat, light and migration fastness

- Good to excellent weather to fastness

|

PVC, PS, LDPE, HDPE, PP, PET

|

|

Phthalocyanine

|

High color strength

|

- Good heat, light and migration fastness

- Good to excellent weathering

|

PVC, LDPE, HDPE, PP, ABS, PA, PET

|

Violet Pigments Violet Pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which Used

|

|

Dioxazine

|

High color strength

|

- Good heat, light and migration fastness

- Medium weatherability

|

PVC, PS, LDPE, HDPE, PP

|

|

Quinacridone

|

Medium to high color strength, bluish red and violet

|

- Good heat, light and migration fastness

- Good to excellent weathering, particularly in TiO2 reduction

|

PVC, HDPE, PP

|

Green Pigments Green Pigments

|

|

|

Family

|

Coloristic Properties

|

Resistance Properties

|

Main Polymers in which Used

|

|

Phthalocyanine

|

High color strength

|

- Good heat, light and migration fastness

- Good to excellent weathering

|

PS, PVC, LDPE, HDPE, PP, ABS

|

What are the popular inorganic pigments used in plastics?

What are the popular inorganic pigments used in plastics?

When it comes to polymers and plastics, inorganic pigments are known to offer several benefits as listed below.

- Easy dispersing

- Heat stable

- Lightfast

- Weatherable

- Opaque

- Insoluble, avoiding migration tendencies

Some of the inorganic pigments, particularly those containing ions capable of more than one oxidation

state (for example Pb, Hg, Cr, Cu, Fe), darken upon exposure. Thermal degradation

generally manifests itself as darkening as well. Inorganic pigments are not shear

sensitive and offer a good value in use.

Certain inorganic pigments exhibit high IR reflectivity for a given visible

color. Inorganic pigments are used in applications requiring surfaces to stay

cool and to withstand outdoor elements, such as roofing, decking, and automotive

exteriors. This allows costs and energy savings but also increases the life of the

substrate by protecting it from damage caused by the heat of the sun.

Yellow Pigments Yellow Pigments

|

|

| Family

|

Heat Resistance

|

Light-fastness

|

Other Properties

|

|

C.I. Pigment Yellow 42

(Iron oxide)

|

160 to 180°C

|

-

|

applicable in rubber

|

|

C.I. Pigment Yellow 34

(Lead chromates)

|

140 to 300°C

|

-

|

more heat and light stable when encapsulated

|

|

C.I. Pigment Yellow 184

(Bismuth Vanadates)

|

240 to 300°C

|

excellent

|

rising importance in the market place (no heavy metals and good properties)

excellent weather resistance

|

|

C.I. Pigment Yellow 53

(Nickel antimony)

|

up to 1000°C

|

-

|

Low tinting strength

|

Orange Pigments Orange Pigments

|

|

| Family

|

Heat Resistance

|

Weather Resistance

|

|

C.I. Pigment Orange 20

(Cadmium Sulfide)

|

400 to 600°C

|

adequate for many applications

|

Brown pigments Brown pigments

|

|

| Family

|

Heat Resistance

|

Light-fastness

|

Other Properties

|

|

C.I. Pigment Brown 6

(Iron oxide)

|

max 180°C

|

excellent

|

applicable in rubber

|

|

C.I. Pigment Brown 29

(Chrome/Iron oxide)

|

300°C

|

excellent

|

high opacity

|

|

C.I. Pigment Brown 31

(Chrome/Iron oxide)

|

300°C

|

excellent

|

high opacity

|

|

C.I. Pigment Brown 33

(Chrome/Iron oxide)

|

300°C

|

excellent

|

high opacity

|

Red pigments Red pigments

|

|

| Family

|

Heat Resistance

|

Light-fastness

|

Other Properties

|

|

C.I. Pigment Red 101

(Iron oxide)

|

up to 300°C

|

excellent

|

available in opaque through transparent form

|

|

C.I. Pigment Red 104

(Mixed Phase Pigment)

|

140 to 300°C

|

increased by stabilization with water glass during production

|

stabilization with waterglass during production

increases weather resistance

|

|

C.I. Pigment Red 29

(Ultramarine pigment)

|

up to 200°C

|

excellent

|

very bluish red shade

|

Blue pigments Blue pigments

|

|

| Family

|

Heat Resistance

|

Weather Resistance

|

Other Properties

|

|

C.I. Pigment Blue 29

(Ultramarine Pigment)

|

300 to 400°C

|

-

|

acid resistance improved by surface treatement

good light-fastness

|

|

C.I. Pigment Blue 28

(metal oxyde)

|

up to 1000°C

|

increased by stabilization with water glass during production

|

excellent dispersibility

|

|

C.I. Pigment Blue 36

(metal oxyde)

|

up to 1000°C

|

-

|

excellent dispersibility

|

Violet Pigments Violet Pigments

|

|

| Family

|

Heat Resistance

|

Light-fastness

|

Other Properties

|

|

C.I. Pigment Violet 15

(Ultramarine Pigment)

|

up to 250 °C

|

excellent

|

acid resistance improved by surface treatment

|

|

C.I. Pigment Violet 16

(Manganese violet)

|

up to 300 °C

|

good

|

-

|

Green Pigments Green Pigments

|

|

|

Family

|

Heat Resistance

|

Light-fastness

|

Other Properties

|

|

Pigment Green 17

(Chrome Oxide Green)

|

1000°C

|

excellent

|

highly abrasive

|

|

C.I. Pigment Green 19

(Cobalt-based mixed metal oxides)

|

300 to 1200°C

|

excellent

|

-

|

|

C.I. Pigment Green 26

(Cobalt-based mixed metal oxides)

|

300 to 1200°C

|

excellent

|

-

|

|

C.I. Pigment Green 50

(Cobalt-based mixed metal oxides)

|

300 to 1200°C

|

excellent

|

-

|

Carbon black: How do they influence plastics performance?

Carbon black: How do they influence plastics performance?

Carbon black is the most widely used black pigment for thermoplastic applications. Its small particle size and high oil absorption bring:

-

excellent color strength,

- cost-effectiveness, and

- ultraviolet performances.

Thanks to its chemical purity, carbon black is a useful pigment for a variety of materials besides plastics. These include elastomers, inks, and surface coatings.

Carbon black may be applied to create full-shade black plastics. It may also be used as a tinting pigment to modify the color of the chromatic pigments in plastics. As a single pigment, the black color that carbon black imparts to the plastic medium is referred to as "jetness".

|

Property

|

Carbon Blacks

|

|

Light Fastness

|

excellent

|

|

Resistance to solvents

|

good

|

|

Chemical Stability

|

excellent

|

|

Heat Stability

|

excellent

|

Influence on Plastics Performances

The particle size and shape of carbon black pigments influence performance attributes in plastic applications. These include:

- Stability against UV radiation

- Mechanical properties

- Electrical conductivity

|

Plastic Performance

|

Fine Particles

|

Large Particles

|

|

Viscosity

|

+

|

-

|

|

Ease of dispersion |

-

|

+

|

|

Wetting speed

|

-

|

+

|

|

Tint strengh

|

+

|

-

|

|

Conductivity

|

+

|

-

|

|

UV absorption

|

+

|

-

|

|

Cost

|

+

|

- |

White pigments: What are the labeling requirements?

White pigments: What are the labeling requirements?

White pigment in plastics is mainly derived from Titanium Dioxide. TiO2 is widely used for its efficiency in scattering visible light. It imparts whiteness, brightness, and high opacity when incorporated into a plastic formulation.

Moreover, titanium dioxide has the ability to absorb UV light energy. This can provide significant improvement in the weatherability and durability of polymer products. This property has established the use of TiO2 in applications such as:

- PVC window profiles,

- agricultural films, and

- in applications that desire chalking stability and color retention.

It is advisable to know about the labeling requirements of TiO2 as well. This is essential while selecting or using titanium dioxide products in your formulation.

In February 2020, the EU classified titanium dioxide as a suspected carcinogen by inhalation. In September 2021, ECHA published a new guide for companies and national authorities. It explains how mixtures containing titanium dioxide need to be classified and labeled. It should follow its classification as carcinogenic if inhaled.

As of 1 October 2021, following Delegated Regulation (EU) 2020/2017, new classification and labelling requirements enter into force.

- The substance TiO2 must be classified as a carcinogen if inhaled Carc. 2, H351 (inhalation) when supplied on its own or in mixtures. The substance or mixture contains 1% or more of TiO2 particles with an aerodynamic diameter ≤10 μm. In addition, mixtures containing TiO2 must be labeled with the supplemental label element ‘Hazardous respirable dust may be formed when used. Do not breathe dust’ (EUH212).

-

Non-classified solid mixtures must also be labeled with the EUH212 supplemental labeling element. This classification implies only if they contain at least 1% of TiO2, regardless of their form, or particle size.

-

Liquid mixtures containing TiO2 do not require Carc. 2 classification. However, if they contain at least 1% of TiO2 particles with an aerodynamic diameter ≤10 μm, then they need to be labeled with the supplemental label element ‘Hazardous respirable droplets may be formed when sprayed. Do not breathe spray or mist’ (EUH211).

Special effect pigments & types: How are they unique?

Special effect pigments & types: How are they unique?

The addition of special effect pigments into plastics allows formulators to:

- Evoke quality, durability, luxury, or tradition

- Impart an emotional dimension upon the product

- Reinforce branding and differentiation

- Provide the material with a sophisticated, fancy, or attractive appearance

Major types of special effect pigments

- Pearlescent pigments - They impart a pearly or metallic sheen to the products they are added to.

- Interference pigments - They produce shifting colors depending on the angle of light and the viewer's perspective. They create an iridescent effect and are often used in plastics.

- Thermochromic pigments - They exhibit reversible color changes at specific transition temperature ranges, which is useful for application such as food and pharmaceutical packaging (indicating storage for example).

- Phosphorescent pigments - They can absorb and store light energy and then emit it slowly in the dark, creating a glow-in-the-dark effect.

- Chromatic pigments - They change color depending on the viewing angle and the angle of incident light. They create a color-shifting effect and are used in various applications.

-

Fluorescent pigments - Fluorescent pigments and light-conducting pigments have intrinsic light-collecting properties. They collect daylight along the edge and re-emit it more intensely, producing a brilliant glow-in-the-dark effect. They can be used to give increased visibility of printing and signs and signals.

-

Photochromic pigments - They change from colorless to highly-colored when exposed to ultraviolet light (such as sunlight) and revert when they are removed from radiation. These are organic pigments and exhibit excellent coloration in a wide range of polymers. They can be mixed to from the spectrum of colors.

Aluminum pigments: When to choose between multiple attributes?

Aluminum pigments: When to choose between multiple attributes?

Aluminum pigments are used in many types of polymers to impart both aesthetic and functional value. There are an amazing number of different aluminum pigment grades. Each grade offers a distinct visual appearance or functional attribute.

-

They can also impart great functional performances to plastics.

- They can also provide additional value to your products.

Aluminum pigments in dry powder form are dusty and easily become airborne. Once suspended in the air, a cloud of aluminum pigment particles will burn explosively. This occurs when these particles are exposed to any source of ignition. These pigments collect in the ductwork of ventilation systems causing additional safety problems.

To minimize these issues, they are provided in a form where a pigment binder or carrier holds the individual pigment flakes together. E.g., Aluminum pigments when used in plastics are commonly provided as a plasticizer-dampened powder or as a pellet. Here, the flakes are bound together with a solid resin.

Pigment Form, Carrier Options and Surface Treatment

A typical aluminum pigment flake is more than just a tiny fleck of aluminum metal. The core of the pigment flake is aluminum metal. This core is surrounded by an extremely thin oxide layer. This layer itself is surrounded by a layer of milling lubricant.

This double sheath of oxide and lubricant handles the behavior of the Al pigment in particular applications. The diagram below shows the arrangement of these three layers.

For use in plastics, the milling solvent needs to be replaced with a medium or carrier. The latter is compatible with polymer chemistry and processing applications. Typically, the milling solvent is replaced with:

- a liquid plasticizer such as mineral oil,

- a phthalate ester, or

- a solid resin.

The bond between the pigment particle and polymer matrix. Both organic and inorganic surface treatments are available. Care is important to choose a surface treatment compatible with the matrix polymer if maintaining physical properties is important. This is because of the differences in chemistry among the many types of plastics commonly pigmented with aluminum.

Influence of Geometry on Effects

The characteristics that help differentiate one grade of aluminum from the other are as follows.

-

Median Particle Size - Usually measured in microns. It is an indication of the average cross-sectional length of the aluminum pigment. The particle size value is usually expressed as the D(50%). This represents the size at which 50% of the flakes in the distribution are larger and 50% smaller. Larger particle size grades are brighter, more reflective, & have more sparkle than smaller sizes.

-

Aspect Ratio - It is the ratio of cross-sectional thickness (T) into the cross-sectional length (D). Aspect ratios from 100 to over 1000 are typical of most milled aluminum pigments. Aluminum pigment grades with higher aspect ratio values will typically have:

- greater surface area and

- better coverage or hiding power.

-

Particle Size Distribution - It is the measure of the difference between the size of the largest and the smallest flakes of any particular grade. The particle size distribution is characteristic of any single grade but can vary greatly from one grade to another.

- Broad distribution ranges have greater hiding power and coverage. They do not produce clean colors when used in combination with chromatic pigments.

- Narrow distribution ranges produce cleaner colors when used with transparent pigments or dyes. But they need higher loading levels to build opacity.

Influence of 3D Shape on Effects

The 3D shape of an aluminum pigment influences the aesthetic effect it is capable of producing. There are three basic geometries - Cornflake, Lenticular, and Spherical. Of the three, cornflake and lenticular are the most common.

Cornflake - As its name implies, pigments with cornflake geometry have a shape similar to that of cornflakes. The peripheral edges are fairly jagged and uneven and the planar surface is uneven and rough. The rough edges and surfaces of pigments with cornflake geometry scatter light as it’s reflected. This produces a diffuse reflectance that reduces specular reflectance and metallic travel. The following photomicrograph is of a typical cornflake pigment grade.

Aluminum Pigment with Cornflake Geometry

Aluminum Pigment with Cornflake Geometry

Lenticular - The second common lamellar geometry is lenticular or round flake geometry. Flakes with this shape tend to have smooth rounded peripheral edges and smooth even planar surfaces. When properly oriented, aluminum pigments reflect more light at the angle of the incident light. It also improves specular reflectance and metallic travel. The photomicrograph below shows pigments typical of this geometry.

Aluminum Pigment with Lenticular Geometry

Aluminum Pigment with Lenticular Geometry

Spherical - The third pigment geometry is spherical. Much less common than either of the two lamellar geometries. Pigments with a spherical shape provide a different type of aesthetic appearance. These pigments provide much less opacity due to their lower surface area. Light reflected from polished surfaces of aluminum pigments produces a pinpoint sparkle effect. The combination of low opacity and pinpoint sparkle produces a shimmering reflectance. This in turn gives the appearance of depth to transparent polymers.

Aluminum Pigment with Spherical Geometry

Aluminum Pigment with Spherical Geometry

Spherical pigments can reduce the appearance of flow lines in injection-molded objects. This is because the brightness of the light reflected from the pigment is less dependent on the viewing angle as compared to a lamellar pigment.

.

Metallic Effects of Aluminum Pigments

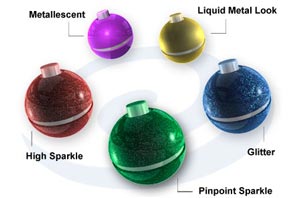

Aluminum pigments are used in many types of polymers to impart aesthetic value. There are an amazing number of different aluminum pigment grades. Each offers a distinct visual appearance. The appearances are divided into 5 major effects as listed and discussed below.

- Glitter Effect - It is a bright metallic appearance with coarse grain sparkles. It is very similar to that obtained when using chopped foil pigments in the 50 X 50 micron to 400 X 400 micron range. Often used to enhance the 3D appearance of an object. This is done by using a low enough concentration of metallic pigment to maintain some polymer transparency. The Glitter effect can be made even more appealing by adding color with transparent pigments or dyes.

- High Sparkle Effect - It is the traditional metallic effect obtained by using aluminum pigments in polymers. Characterized by a strong metallic sheen and often a noticeable grain. It uses a combination of metallic pigment concentrations & transparent or opaque chromatic pigments. They produce broad effects characterized by distinct metallic sheen and sparkle

- Metallescent Effect - It is a soft diffuse translucent metallic appearance. It is similar to the effect obtained by using pearlescent pigments. This effect, or Metallescent appearance, is developed only when using the proper aluminum pigment. The pigments are used at very low loading levels in conjunction with transparent colorants.

- Pinpoint Sparkle Effect - It is unique due to the spherical and polished surface of the aluminum pigments used to produce it. The effect is seen as a cascade of shimmering pinpoint reflections of light. This effect can give "depth" to transparent polymers. This is done by producing sparkling reflections that come from below the polymer surface. When used with transparent colorants and viewed under bright light this effect is quite dramatic. As an added benefit, the Pinpoint Sparkle effect can help reduce the appearance of flow lines in injection molded parts.

- Liquid Metal Effect - It is a bright metallic effect. Produces the appearance of pure metal such as brushed aluminum or polished steel. Characterized by a smooth liquid metallic sheen and controlled grain or no grain. The Liquid Metal look can also produce the appearance of anodized aluminum. Aluminum pigments used to produce the liquid metal effect give polymers the appearance of having been made from solid metal.

Functional Performances

Although used for aesthetic effects, aluminum pigments add value through their physical attributes. They can improve the functional properties of polymers in a variety of ways.

Their ability to add functional value to polymers is due to the nature of the parent metal and the 3D features of the pigment particle. These characteristics include:

- Metallic Luster,

- Reflectance,

- Opacity,

- Surface Chemistry,

- Particle Geometry,

- Average Particle Size, and

- Particle Size Distribution.

Other less-known applications for aluminum pigments based on their functional attributes are as follows.

Light Reflection

Aluminum pigments are often used to impart reflective properties to blown film due to:

-

the natural ability of aluminum metal to reflect light and

- the lamellar shape of the aluminum pigment particle.

The blown film is used in agricultural applications to reflect sunlight back onto plants with the effect of improving crop yield.

The metallic luster produced by light reflected from aluminum pigments is also used in applications with polymers to replace bulk metal. In these applications, the polymer takes on the appearance of being made from solid metal. It exhibits the structural properties of the polymer itself. The value of this application includes weight reduction. It has the ability to produce complex-shaped parts without having to be machined.

Opacity

Since light is reflected but not transmitted by aluminum pigments. They are often used to impart opacity to polymers. Typical aluminum pigments have a lamellar geometry that maximizes their surface area. Aluminum pigments are capable of building high opacity at low loading levels due to:

- the opaque nature of aluminum metal and

- the high surface area of the lamellar pigment particle.

Light-blocking window shades are often made by laminating a thin opaque Al-pigmented film between the visible outer layers of the window shade.

The opacity imparted by low loading levels of aluminum-pigmented film is also used for trash bags and shopping bags. In these applications, a combination of both the reflective and light-blocking abilities of aluminum pigments is apparent.

Bags made with Al-pigmented blown film keep the contents hidden. It also provides strength due to the metallic luster of the aluminum pigment. The combination of opacity and metallic luster is also used in blow molding applications, for consumer product containers. This application also provides protection from harmful UV radiation.

Gas & Vapor Barrier

Aluminum pigments can improve polymer resistance to gas and vapor transmission. This is accomplished by:

- the impermeable nature of aluminum metal and

- the lamellar shape typical of aluminum pigments.

Aluminum pigment flakes with a fairly broad particle size distribution range will orient themselves in an overlapping manner in most processing applications. This configuration blocks any direct pathway through the polymer. Gas or vapor molecules must take a convoluted and lengthened pathway to penetrate the polymer.

A thin wall container pigmented with lamellar aluminum flakes will offer the gas and vapor protection of a much thicker wall container. For effective barrier protection, the Al pigment flake must be bonded to the polymer matrix during processing. This can be accomplished by using aluminum pigments with the proper surface treatment.

Thermal Conductivity

In certain applications, it is desirable to produce a polymer object with the thermal properties of metal. By comparison, aluminum has:

- greater thermal conductivity,

- lower thermal emissivity, and

- different thermal expansion characteristics than most polymers.

Polymers can be added with aluminum pigments having high aspect ratios. The polymer will start to take on the thermal properties of aluminum metal. Polymers loaded to 40% by weight with a high aspect ratio aluminum pigment have been shown to exhibit heat transfer rates of 80% to 95% that of pure metal. This is important when making polymer-based utensils such as warming trays for use in cooking applications.

What are the processing solutions for pigments used in plastics?

What are the processing solutions for pigments used in plastics?

While processing pigments for plastics, you definitely need to keep in mind the couple of important points as discussed below.

Heat Resistance

Heat is necessary when processing polymers. However, it can be detrimental to polymer and colorant properties. It is important to know exactly the conditions which will be employed when processing. This is especially true when considering that many plastic articles which are produced have actually been subjected to heat on more than one occasion. This is called heat history. Some pigments show intolerances to such heat histories, with a dramatic drop in properties after more than one process. Heat resistance is always defined by both temperature and dwell time during which colorant was exposed to that temperature.

Typical test methods used to rank the heat resistance of pigments in plastics polymers are listed below.

- Heat resistance in PVC - EN 12877-3

- Heat resistance in Polyolefins - EN 12877-2 Procedure A

- Heat resistance of inorganic pigments

- Heat resistance of organic pigments

Dispersion

Excellent pigment dispersion in the final product is essential to its performance. Defects caused by non-dispersed pigment particles (specs) can result in a severely lowered performance level. With good dispersion of pigments the following problems can be avoided.

- Color inconsistency, loss in color yield, batch-to-batch shade deviation,

- Negative effects to the physical and mechanical properties of the final product

such as loss of electrical properties in wire & cable applications,

- Negative processing effects such as filter blockage, breakage of the fiber or undesired

splitting of the blown films,

The combination of optimized processing conditions, pigment selection, and dispersing agent can help you achieve good dispersion and avoid some of the problems listed above.

The more finely the pigment is dispersed (smaller average particle size), the larger the total surface area of the pigment particles and the greater its color strength.

In some cases, dispersion of organic pigments is quite difficult to achieve. The

use of predispersed pigments is recommended when coloring engineering plastics and

for some PVC applications. They offer greater shade consistency and reproducibility.

They remain unaffected by agglomeration by high shear high speed mixers during dry-blending,

and have higher color strength (at representative comparable concentrations), purity

and transparency.

Compaction

Compaction is the re-agglomeration, by mechanical means, of the pigment to form hard particles that are virtually impossible to disperse. This can take place in mixers, feeders, or compounding machinery. Compaction occurs when pigments and polymers are exposed in the solid state, to increasing pressure and friction. Certain pigments can be more prone to this phenomenon than others. The sensitivity of pigments to compaction depends upon the physical properties of the specific pigment. These phenomena can be avoided by handling, storing and generally treating the colorant carefully.

The reagglomeration tendency is illustrated in the table below.

Crystals + agglomerates (normal view) (L) & Compaction (normal view) (R)

Find Suitable Pigments for Polymers

View a wide range of pigment grades available in the market today, analyze technical data of each product, get technical assistance or request samples.